A leading manufacturer’s representative firm

CALL US AT 817-484-5696 • KELLER, Texas

The Founders Group Manufacturers

40+ Years Experience

Since 1971, Water Control has been helping architects, engineers, plumbing/mechanical contractors, and industry distributors to solve their clients’ difficult water problems. With 40+ years experience, there are very few water issues we can’t effectively address. Water Control has complete commercial / residential offerings.

Located just outside Minneapolis, MN, our team of professionals includes mechanical designers, engineers, CAD™/Revit™ technicians, licensed plumbers, controls experts, customer service specialists, service technicians, and outside sales staff. With a network of quality independent representatives around the USA and Canada, we provide local-level service and solutions.

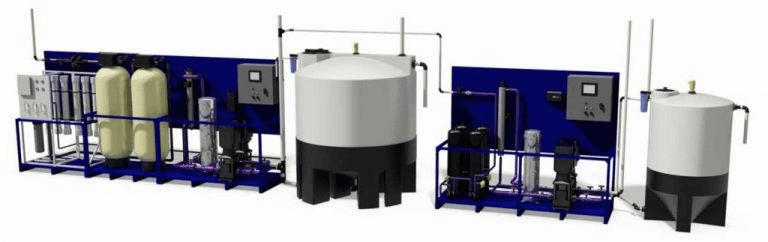

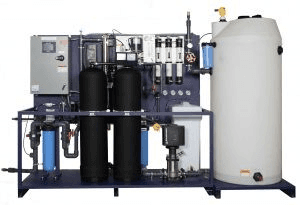

Beyond traditional water softening, Water Control provides a huge array of treatment system options:

high-capacity ultrafiltration

ion exchange

membrane filtration

disinfection technologies

water reclamation packages

and more

End users of our equipment include local, state, and federal institutions, universities, health care providers, well-known InfoTech companies, homeowners, resort owners, and manufacturers both large and small.

We’d love to work with you. Please contact us today to get started!

CONTACT THE FOUNDERS GROUP

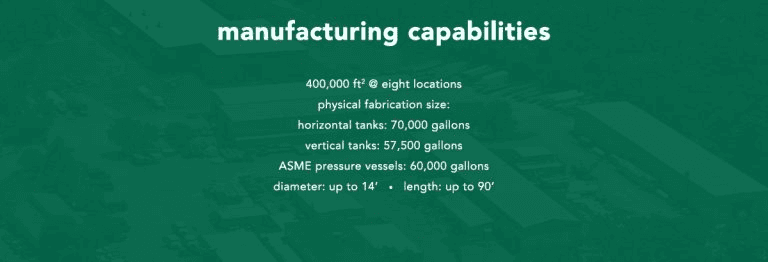

Since 1946, Highland Tank has held a tradition of providing uncompromising craftsmanship and a commitment to providing solutions to even the most challenging tank and vessel projects. Our extensive product line includes petroleum and chemical storage tanks, wastewater treatment systems, water storage tanks and systems, and ASME pressure vessels.

CONTACT THE FOUNDERS GROUP

ABT PolyDrain

POLYDRAIN TRENCH DRAIN SYSTEM

The PolyDrain polymer concrete trench drain system is well suited to a wide variety of surface drainage applications. The ABT PolyDrain precast trench drain system provides modular design flexibility, facilitates construction accuracy, requires less installation labor and skill, and has lower installed cost when compared to conventional hand-formed cast-in-place methods of creating trench drains.

PolyDrain polymer concrete trench drain components have superior chemical resistance, greater strength, lower water absorption, and better freeze/thaw resistance than does Portland cement concrete. Polymer concrete is not degraded by salt, oil, most acids and alkalis, and offers UV resistance. These polymer concrete properties make ABT PolyDrain trench drains excellent for capturing, containing, and transporting surface runoff in any drainage application.

ABT TrenchFormer

TrenchFormer is a pre-engineered, cast-in-place concrete forming system for forming surface drainage trenches, catch basins, utility chases, and voids in concrete placements. The system includes expanded polystyrene (EPS) form profiles, steel inlay rails, patented no-float legs, grates, and grate retainers. TrenchFormer is available in various width, depths, slopes and trench bottom configurations. TrenchFormer replaces hand-forming, heavy materials, keyways and waterstops normally required with trench drains and utility chases.

Its components are made in the most commonly constructed sizes. TrenchFormer consists of 8 ft. (2.4 M ) pre-sloped form segments. Former sections are available in a variety of slopes.

The segments have integral deforming grooves for easy removal and full length longitudinal grooves for coplanar rail spacing.

The steel components are angle rails with anchoring studs welded on 11 in. (280 mm) centers to the outside corners. 1/2 in. (12.7 mm) threaded U-shaped no-float legs attach to horizontal tabs on each rail. Each rail end is designed to accept a Rail Alignment Clip which retains adjacent rail segments.

Prefabricated L-rail and T-rail assemblies allow for field installation of 90° turns anywhere in the pre-sloped layout. These assemblies have rail reinforcement built into the areas where the grates are unsupported in other systems. This reinforcement provides load capacity for AASHTO H2O load ratings.

Outlet piping is butted to an annular groove made in the EPS form prior to concreting. For trench junctions or for large outlet sizes, four catch basins are provided. A selection of gratings and solid covers is available for various loadings.

CONTACT THE FOUNDERS GROUP

The Missing Link for Roofing Systems

The VAULT® is a Single, Secure Pathway to the Roof for Pipes, Conduits, Telecommunication Cables, and More.

It’s no secret – roof pathways are one of the weakest parts of the roofing system. Every new penetration adds cost and increases the risk of future leaks. That’s why we created the VAULT®, a “roof penetration housing” that provides a single, secure pathway to the roof for multiple pipes, conduits, telecommunication cables, and more. Our all aluminum assembly is weather-tight, and comes with a 20-year warranty. So you can start saving time and money on your next project. Because “Nothing Protects Like A VAULT®.”

Who is the VAULT® for?

The VAULT® isn’t just for MEP. It can be used whenever you need a pathway to the roof. Here are some examples of the types of industries that are using the VAULT®:

Solar Energy

Satellite

Security

Electrical

Telecommunications

Duct Work

Plumbing

Refrigeration

Heating

Air Conditioning

Fiber Optic

Microwave

CONTACT THE FOUNDERS GROUP

Kusel’s stainless steel drainage products are built to last in real world applications. That’s why engineers, contractors, and plumbers all know that when they choose a Kusel drain, they’re getting a product they can count on. From large-scale developments to smaller projects, standard drains to custom pieces, our team has the experience to provide the solution you need for every job.

CONTACT THE FOUNDERS GROUP

At Speakman we believe the secret to a great day is a great shower. Recent design renovations to our showerheads resulted in sustained performance quality with a fresh, opulent appeal. The Speakman legacy continues with the introduction of Shower and Bath Collections to complete the luxury bathroom experience. View Speakman shower products

Meet our Rainstream Rain Shower, specifically engineered to deliver a drenching, soaking, sensual experience.

A Stronger Way to Save

Meet the Reaction Shower Head. Equipped with our TempoFlo™ Technology, this water-saving shower head delivers pulsating sprays that are statistically proven to outperform competitor models both in force and thermal retention.

Don’t Let the Valve Stop You

Our Universal Valve Trim is built for your imagination. With the capability to retrofit to select competitor valves, your design decisions will never be restricted by the plumbing. Let your dreaming begin.

CONTACT THE FOUNDERS GROUP

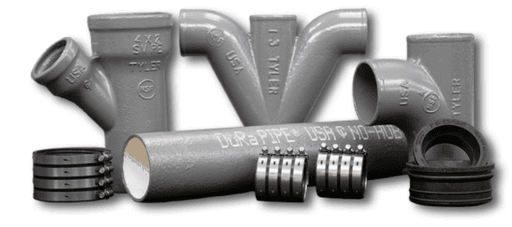

Anaco NO-HUB couplings have been produced since 1963 originally under license from the Cast Iron Soil Pipe Institute. Upon their introduction, they became the immediate alternative to the older method of joining conventional hub and spigot pipe fittings by caulking with oakum and lead and the later method of compression gaskets.

Today Anaco’s coupling is providing the perfect answer for joining hubless cast iron pipe and fittings in drainage, waste and vent systems. The anaco coupling is flexible, not only enabling it to accommodate possible disparities in mating pipe but also providing a permanent seal which is superior to other, more rigid types of couplings.

Since 1963, Anaco has been the leader in no-hub coupling technology. From our complete line of Standard No-Hub couplings, to Husky 4000 and 2000 series, to both shielded and unshielded transition couplings, Anaco produces the broadest line of couplings for connecting cast iron in DWV systems, as well as connecting cast iron to virtually all types of DWV pipe and fittings.

See the Husky Difference, with Anaco-Husky Couplings

How To Correctly Install Anaco-Husky Couplings

CONTACT THE FOUNDERS GROUP

The Milwaukee Valve Company was established in Wisconsin in 1901, starting out as a small manufacturer of plumbing and heating valves. Herschel Seder purchased the business in 1959, with his late partner, Max Koenigsberg. Over the years, the company expanded its offering to what now consists of over 5,000 items, used in a very wide range of applications and industries, from very small plumbing valves used in the basement of your home, to large petro chemical valves and nearly every size and style of valve in between.

Our factory operations are supported by our continual reinvestment in equipment and machine tools, which enables us to maintain very tight control on our part manufacturing. This translates to more predictable and successful performance of the final products once they’re installed. A significant portion of our business is with the US Navy, directly and indirectly. As a result, the highest possible quality standards that our Navy requires for the valves they buy are applied throughout our operation to everything we do. Because of our long-standing position as an important supplier to the Navy, they have trusted us with several key high tech development programs for the newest generations ships and aircraft carriers now being made, something that further distinguishes us from our many competitors.

Milwaukee Valve showcases its operations to Newport News Shipbuilding

CONTACT THE FOUNDERS GROUP

TYLER

ENHANCED EPOXY COATED CAST IRON PIPE & FITTINGS FOR AGGRESSIVE APPLICATIONS

DuRa Pipe™ is an enhanced epoxy coating applied to cast iron soil pipe and fittings made in the U.S.A. DuRaPipe™ is well-suited for aggressive DWV applications where greater performance is required. This is not an equivalent or viable option for acid waste pipe.

Standard cast iron pipe and fittings perform exceptionally well in most applications. However, the DuRa Pipe™ enhanced epoxy coated cast iron solution offers significant advantages for aggressive applications.

● Commercial Kitchens

● Hospitals and Medical Office Buildings

● Casinos

● Soda Fountains

● Seasonal Occupancy Buildings

● Any area with exposure to chemicals from pH 2

to pH 12

DuRa Pipe™ enhanced epoxy coating begins with the same high quality cast iron pipe we have always made. However, instead of being dipped in an asphalt coating, the pipe is coated inside and out with a two-component, solvent free, epoxy that provides additional protection against corrosive environments.

Fittings are fully coated with a fusion bonded epoxy that provides the same additional protection against corrosive environments. DuRa Pipe™ is available in ranges from 2” to 15” No-Hub and Hub & Spigot (Service Weight) in 10’ lengths.

These products conform to ASTM A 74, ASTM A 888, CISPI 301 standards. It is certified by NSF International complying with performance and quality requirements of all standards.

For Installation guide, please reference the following:

https://www.tylerpipe.com/resources/technical-data/

installation-guides/

Where an on-site coating of the cut edges is desired or specified, it is recommended to use PPG Multi-Prime 4160 or Fast Dry 4180 coating following the instructions on their data sheet.

Multi-Prime 4160:

https://www.ppgpmc.com/products/MULTIPRIME-4160

Fast Dry 4180:

https://www.ppgpmc.com/products/FAST-DRY-4180

SPECIFICATIONS

● DuRa Pipe™ coated pipe and fittings shall

conform to the requirements of CISPI Standard

301, ASTM A888 and ASTM A74, and be coated with

a suitable epoxy coating. Pipe and fittings shall

be marked with the collective trademark of the

Cast Iron Soil Pipe Institute and be listed by NSF

International.

● Each pipe and fitting shall be plainly marked

with date of manufacture (pipe only), country of

origin, and name of manufacture or manufacturer’s

registered trademark by which the manufacturer

can be readily identified after installation.

CONTACT THE FOUNDERS GROUP

Hammond Valve

SportsEdge

Founded and based in Texas

101 Bourland Rd., Suite E, Keller, TX, 76248

© TFG Founders Group 2017. All Rights Reserved.

CALL US AT 817-484-5696 • KELLER, Texas